Our unique advantages

Designed for logistics: Flexible & fast in use

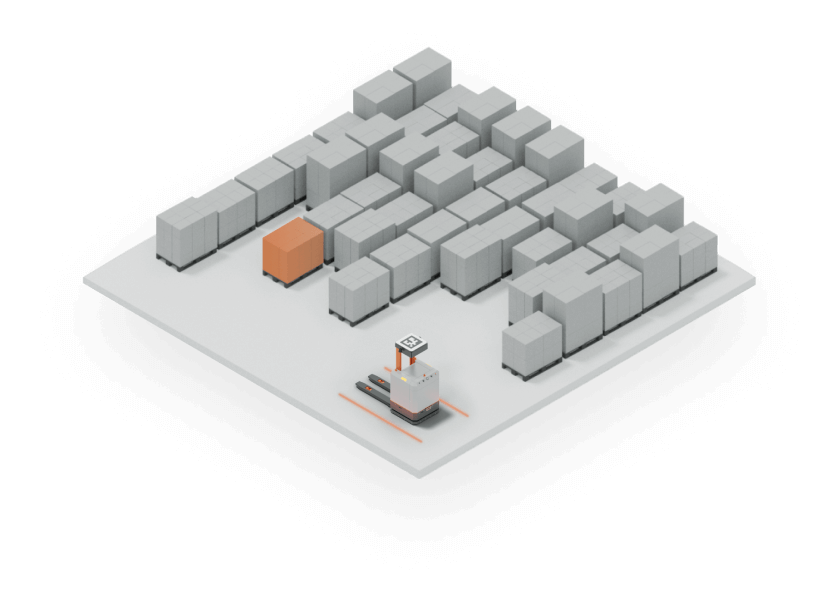

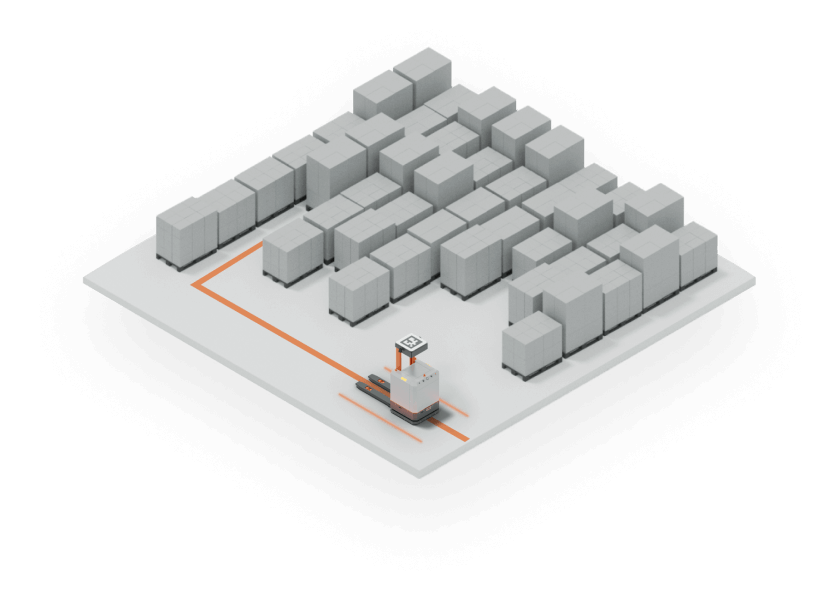

Block storage expert

The only mobile robot for robust block storage! Thanks to patented localization technology, the PIXEL PT fills and empties block storage systems of any depth. No predetermined transfer points required.

Ready to use

Automates your process without changes and WMS integration.

Cameras recognize goods fully automatically and trigger suitable transport orders.

Designed for fleet operation

The W2MO fleet manager coordinates AMRs and manual transports and maps processes easily – including buffer areas and load transfer points.

The real-time digital twin makes it easy to implement optimizations and integrations.

PIXEL PT

Designed from scratch, the PIXEL PT is an Autonomous Mobile Robot (AMR) based on a lean, modular, and robust hardware concept. The PIXEL PT was developed to enable automated intralogistics workflows in fast-changing and rough industrial environments. The vehicle combines proven hardware of industrial trucks with the latest safety and camera technology. With its 3- wheel geometry and slim design the PIXEL PT can navigate through tight spaces and narrow aisles.

Max. Speed: 1,5 m/s

Max. Lifting Weight: 1300 kg

Min. Aisle Width: 1000 mm

Continuous operation time: 8-16 h

Field-tested vehicle for harsh logistics environments

Automatic charging

Thanks to the use of Li-Ion technology, the PIXEL PT is highly available due to short charging times and up to 16 hours of continuous operation. During periods of low productivity, the AMR automatically docks to the nearest charging station.

Robust undercarriage

Logistics are tough – with a drive wheel diameter of 28 cm, even large expansion joints and floor sills are no problem for the PIXEL PT.

Fork detection

The innovative, AI-based fork detection recognizes and drives around forklift forks. Unlike conventional 3D cameras, it is robust against uneven floors.

Advanced navigation

The digital twin enables precise and reliable navigation in crowded and fast-changing environments

Pallets can be picked up anywhere. No pre-determined transfer points required.

The data from the digital twin allows flexible obstacle avoidance.

Robots can interact with forklifts and other manually-driven vehicles.

How it works

The enabler: AI recognition units distributed on the ceiling

AI recognition units placed on the ceiling track everything in real time

They analyze the shop floor for obstacles and vehicles

Determines the availability of target locations

A digital twin is created and used for navigation and fleet management

Company

Pixel Robotics GmbH builds intelligent, perception-controlled robots tailored for logistics. With its unique AI vision infrastructure a digital twin of the operating area is created. Using this real-time twin, Pixel Robotics’s robots work together with their human colleagues – autonomous, safe and with an unmatched level of flexibility.

Pixel Robotics is headquartered in Munich.

Hot openings

Benefits:

- Start-up atmosphere in a fast-growing and rapidly evolving company

- A centrally located office next to the Olympic park

- Extras such as free drinks, fruits, and a job ticket

- Flat hierarchies and room for growth

Partners